Resin Diamond Wheel For Grindi

ResinDiamondWheelforgrindingandchamferingResindiam...

Read More >Home :News / Company news / BrowseArticle

ResinDiamondWheelforgrindingandchamferingResindiam...

Read More >

TRAPEZOIDALEDGEDIAMONDWHEELS(FA)OFPRODUCTINTRODUCE...

Read More >

Fullsegmenteddiamondgrindingwheel,Itisproducedbyth...

Read More >

Manypeoplehavethisexperience:glasseasilybrokenordr...

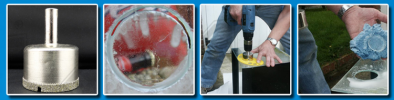

Read More >Full segmented diamond grinding wheel, It is produced by the diamond powder and metal bond sintering with high temperature and high pressure. since the working surface is serrated and which is called the diamond wheel teeth, tooth layer can also provide space for drainage chip in the working, reduce the burning and chipping glass from caused by high temperature ande pressure, and also can improve the wear resistance of the cutting force of the diamond wheel.

Details Parameter of Full segmented diamond grinding wheel:

Outer Diameter: 150mm, 175mm.

Inner Diameter: 12,22,50,70

Grit: 80#, 100#

Advantages of Full segmented diamond grinding wheel;

1, High efficiency, deeper cutting depth, fast removing ability of the glass uneven edges.

2, Good sharpness,no edge chipping while grinding.

3, Smooth glass edge after processing.

4, Long service life, reduce the frequency of replacing grinding wheel in periodic time.

Aplication of Full segmented diamond grinding wheel:

Diamond Cup shape wheel is metal bonded diamond wheel, Full Segmented rim, which is used for 3-25mm flat glass / laminated glass edge grinding on Glass Straight or Double Edging Machines.